Cooling performance is the most important requirement for pistons used in high-power turbocharged engines. When high power is generated, the area around the piston is subjected to a harsh environment of high temperature and high pressure, so it is essential that the piston be strong enough to withstand these conditions. Forging the material provides the necessary strength to withstand high combustion pressure, but increasing the material strength is not sufficient to withstand the increased heat load. Even with forging, the strength of the material is significantly reduced by temperature rise, thus the need for cooling. The common method of piston cooling is to inject extra fuel to utilize the heat of vaporization, but an excessively large amount of fuel will not only cause a loss of power due to a deteriorated air-fuel ratio, but will also dilute and degrade the engine oil and cause the engine to overheat. However, excessive fuel consumption not only reduces power by deteriorating the air-fuel ratio, but also dilutes and degrades the engine oil, causing dilution, which is damaging to the engine.

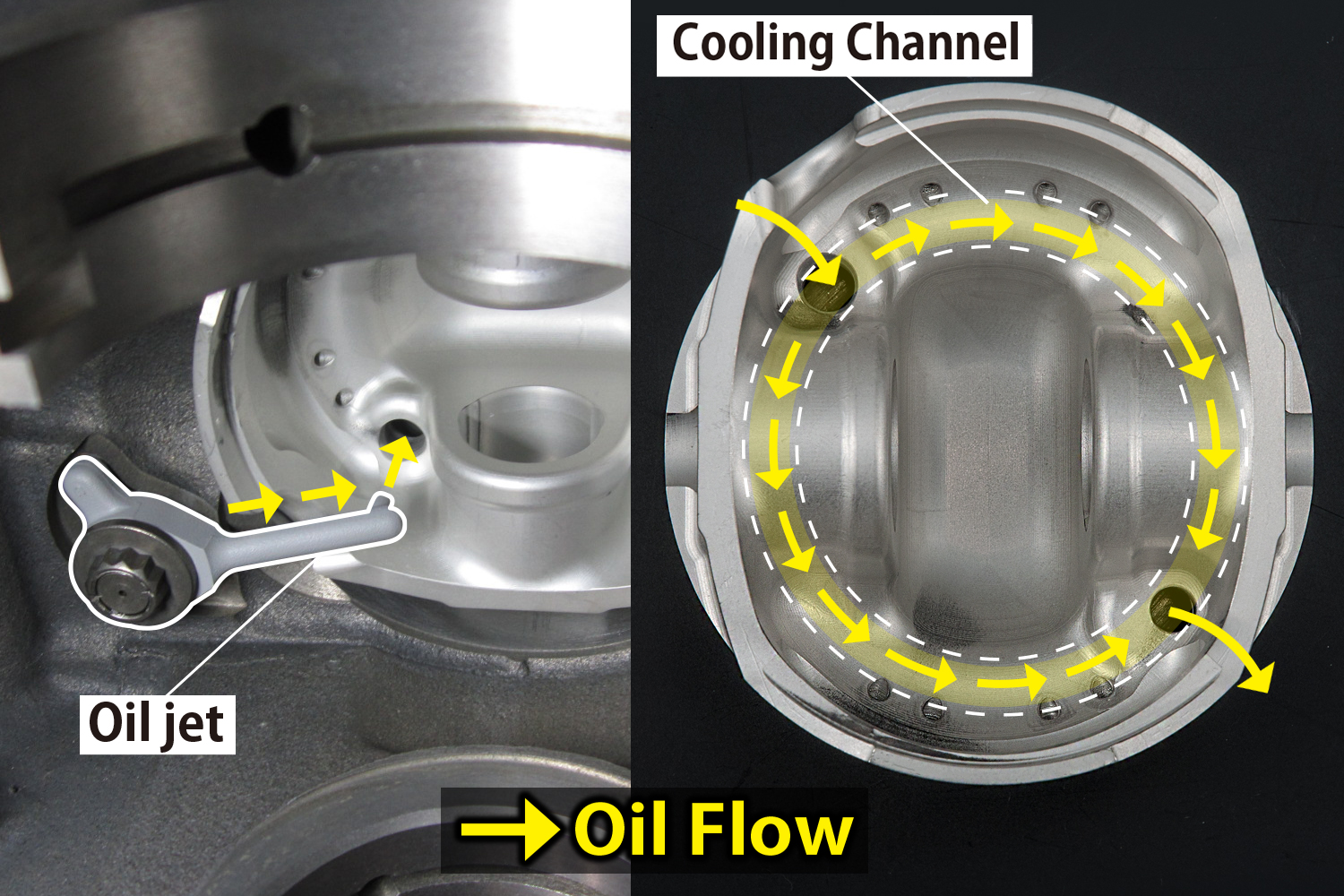

Cooling channels are a useful cooling method without such disadvantages. Cooling channels are ring-shaped cavities located behind the piston ring grooves, and by circulating engine oil through them, the pistons can be cooled efficiently. In addition, the area around the ring groove, which is prone to high temperatures, is cooled intensively, which maintains an ideal clearance between the piston and rings, improves the sealing of combustion gases, and helps convert combustion energy into power without loss. A engines, this excellent cooling performance has achieved both high power output and high reliability.

We have paid particular attention to quality when commercializing this product. High-quality Japanese forged materials are used for the materials, and the cutting process is carried out by a machining company that specializes in racing pistons. The piston profile, which is the key feature of the piston, is faithfully reproduced according to the dimensions of the original development drawings using the advanced machining technology cultivated through the development of racing pistons, which require strict accuracy requirements. Although it is a costly process to make a forged piston with cooling channels, we have followed the original manufacturing method without sparing any expense. Although the piston is structurally a two-piece structure, it is welded by electron beam welding, which allows for deep penetration and minimal distortion.

※Piston rings, piston pins and circlips included

※Compatible with STD connecting rods

※Reference compression ratio (head G/K t=1.2mm): φ86=8.1, φ86.5=8.2

※Refer to the specified values in the product manual for piston clearance.

Reviews

There are no reviews yet.